Level Relay

The ELKO EP liquid level relays are designed to monitor and control the levels of liquids in tanks, reservoirs, and other containers. These relays are essential for various applications, including water supply systems, wastewater management, and industrial processes where maintaining precise liquid levels is critical. Here are the key features and benefits of ELKO EP liquid level relays:

Key Features:

- Versatile Monitoring:

- Multiple Probes: Can be connected to multiple probes to monitor different levels (e.g., minimum, maximum) within the container.

- Adjustable Sensitivity: Allows fine-tuning to accurately detect the presence or absence of liquid at the probe points.

- Control Functions:

- Automatic Pump Control: Can control pumps to fill or empty the container based on the detected liquid levels.

- Alarm Output: Provides an alarm signal if liquid levels deviate from the set parameters, ensuring timely intervention.

- Digital Display and Indicators:

- Real-Time Readout: Displays current liquid levels and relay status for easy monitoring.

- LED Indicators: Show the operational status of the relay and the level sensors.

- Programmable Settings:

- Customizable Parameters: Users can set specific thresholds and control logic to match their application requirements.

- Delay Settings: Prevents false triggering due to turbulence or temporary changes in liquid level.

- Durability and Reliability:

- Robust Construction: Designed to withstand harsh environments, ensuring long-term reliability and performance.

- Electrical Isolation: Provides safe operation by isolating the control circuit from the monitored liquid.

Benefits:

- Automated Control: Enhances system automation by automatically managing liquid levels, reducing the need for manual intervention.

- Safety: Prevents overflow and dry-running of pumps, protecting equipment and ensuring safe operation.

- Efficiency: Optimizes pump usage and reduces energy consumption by maintaining precise control over liquid levels.

- Versatility: Suitable for a wide range of liquids, including water, wastewater, and various industrial fluids.

Applications:

- Water Supply Systems: Monitors and controls water levels in tanks and reservoirs to ensure a consistent supply.

- Wastewater Management: Manages liquid levels in wastewater treatment plants to prevent overflow and ensure efficient processing.

- Industrial Processes: Controls liquid levels in various industrial applications, such as chemical processing, food and beverage production, and cooling systems.

- Agriculture: Maintains water levels in irrigation systems and livestock water troughs.

Example Models:

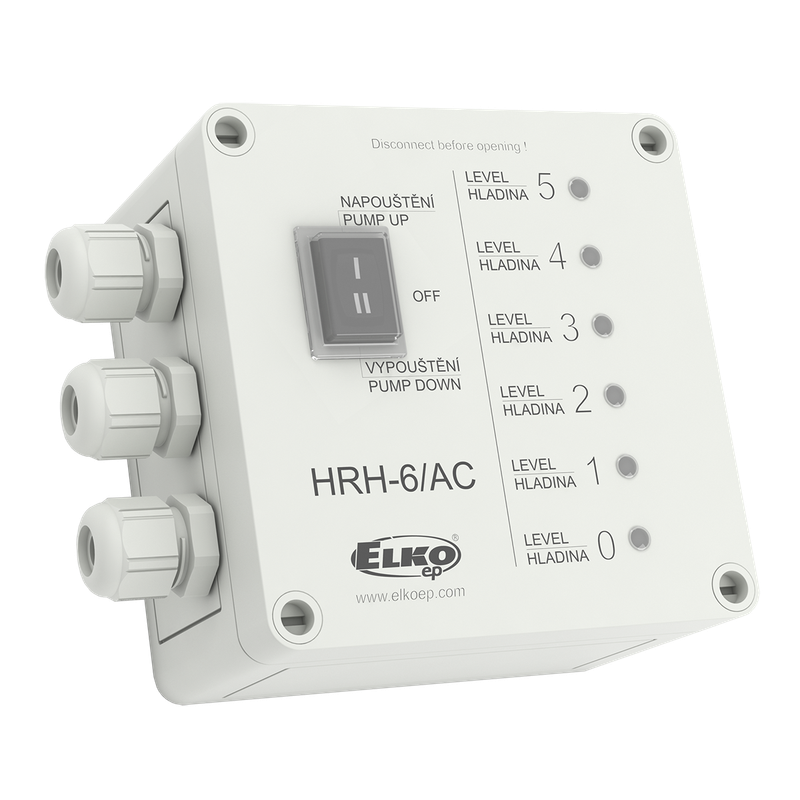

- ELKO EP HRH-5: A versatile liquid level relay suitable for a variety of applications, featuring multiple probe inputs and customizable settings.

- ELKO EP HRH-3: Designed for simpler applications with basic level monitoring and control functions.

- ELKO EP HRH-6: Advanced model with additional features such as multiple relay outputs and enhanced sensitivity settings.

Installation and Programming:

- Installation: Mount the relay in a suitable location near the monitored container. Connect the probes according to the provided wiring diagram, ensuring they are properly placed to detect the desired levels. Connect the relay to the power supply and any controlled devices (e.g., pumps, alarms).

- Programming: Use the digital display and control buttons to set the desired parameters, including sensitivity, thresholds, and delay settings. Follow the user manual for detailed instructions on configuring the specific model.

Would you like more detailed information on a specific ELKO EP liquid level relay model, or assistance with installation and programming?